You have access to this full article to experience the outstanding content available to SPE members and JPT subscribers.

To ensure continued access to JPT’s content, please Sign In, JOIN SPE, or Subscribe to JPT

The traditional subsea tieback model is evolving, supported by advances in flow assurance that allow tiebacks over much longer distances and by the introduction of new technologies that increase overall cost effectiveness. Paper OTC 30667 discusses several of these technologies, their maturity status, and how they can be integrated economically.

Introduction

During the past 15 years, operating companies have relied increasingly on effective subsea field-development solutions to eliminate the need for traditional platforms or vessels with topside processing facilities, particularly in geographically remote areas and small-pool developments of maturing brownfield areas. Technical and economic challenges include flow assurance and the cost of the umbilical and flowlines, which increase with length. These aspects, together with others independent of length, such as power and space availability, affect project economics significantly.

Technologies developed recently or in their final stage of qualification can help not only in solving technical challenges but also in finding cost-effective configurations, either through reduction or reapportioning of capital and operational expenditures, extension of reserves recoverability, or reduction of associated risks.

The complete paper outlines several configurations, beginning with those enabled by conventional technologies, and compares them to those enabled by the new technologies. Each section of the complete paper discusses the subject technology’s composition, application, maturity, and impact on cost effectiveness.

Subsea Boosting

Subsea boosting systems that ensure pressure to enable production flow for the life of the field have matured during the last 10 years. Boosting can reduce backpressure at wellheads, and also can transport the production fluid at higher pressure to minimize flowline diameter and control possible instability issues. For gas fields, recovery can be increased by allowing the reservoir to deplete and then using compression to produce the field over a longer time. Currently, several boosting systems operate internationally.

The type of pump technology used depends on the fluid to be boosted and the performance required. Single-phase pumps are used for water injection and oil boosting up to 15% of gas/volume fraction (GVF). Hybrid pumps are used for GVF up to 30%, and multiphase pumps for up to 95%. Subsea compressors are used for higher GVF.

For gas reservoirs where small amounts of condensate and water can be produced, two options exist:

- Gas/liquid separation and a liquid pump and dry gas compressor can boost each phase independently and recombine the boosted phases for a multiphase export to the host facilities.

- A wet gas compressor can be used to boost both phases simultaneously.

The complete paper discusses related installations and cost-effectiveness studies.

Distributed Heating

Distributed heating is used primarily to maintain the fluid above the hydrate-formation temperature (HFT) in the flowline during a production shutdown (preservation mode) and to warm the fluid above the hydrate-dissociation temperature following a long shutdown before resuming production (restart mode). In some cases, distributed heating also can be used during production to ensure a steady-state arrival temperature (SSAT) at the host above the wax-appearance temperature (WAT) or critical-wax-deposition temperature (CWDT). Generally, if heating is required during production, it is limited to turndown conditions.

For gas fields, distributed heating can also be used continuously during production to remain above the HFT or WAT, removing the requirement for permanent hydrate-inhibitor injection at wellheads.

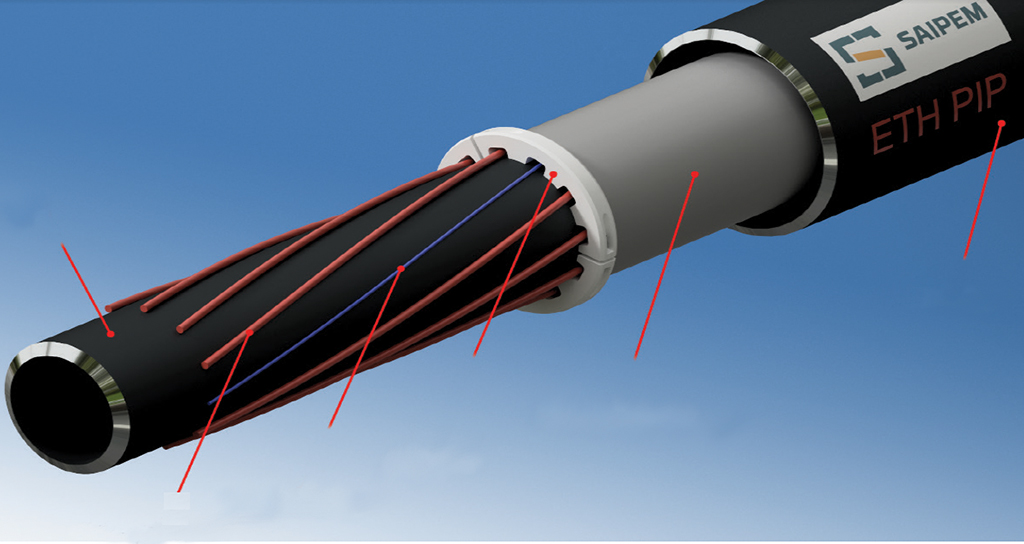

Subsea distributed heating can be ensured by direct-electrical heating (DEH) or electrical-trace heating (ETH). Even if both technologies can be combined with pipe-in-pipe (PIP) or wet-insulated single pipe, the two main methods on the market are wet DEH and ETH PIP. Both products, including installations, are described in detail in the complete paper. According to the authors, the main advantage of the ETH PIP is its efficiency of greater than 90%, which limits power consumption. On the other hand, a power chain is needed, including topside equipment, subsea power cables, and flowline electrical components.

Capital expenditure (CAPEX) savings from the heating system depends on project specifics and should be evaluated during the conceptual phase with collaboration between operator and contractor. Some industry studies have shown savings up to 30% compared with a conventional base case for a brownfield development.

Local Heating

Local heating heats the fluid over a short section of the subsea system. The approach can be used to provide a local temperature boost to the fluid during production to ensure SSAT at the host above the WAT or CWDT, or to ensure that the required cool-down time is achievable. It can be required for cold and waxy fluids regardless of water depth, or to compensate for temperature drop caused by gas expansion in the risers for deepwater fields. It also can provide a local temperature boost to the fluid during cold restart to accelerate reheating time and, consequently, reduce the quantity of hydrate inhibitor injected at the wellhead.

According to the authors, local heating is not aimed at competing with distributed heating, but rather at increasing application of traditional loops by adding thermal energy when and where it is needed. The main economic advantage of local heating is reduction in operating expense by eliminating the need for pigging operations in short tieback lengths in deep water.

Subsea Water Treatment and Injection

In a typical greenfield water-injection project, seawater is taken from the surroundings of the floating production, storage, and offloading vessel, treated onboard, and injected into the reservoir through a dedicated riser and flowline network. Subsea water-treatment systems remove various elements from the surrounding seawater that could be detrimental to reservoir health during injection.

Because the subsea injection station can be located close to the well, the need for high-pressure flowlines is reduced and the need for associated risers is removed. The approach also offers technical and financial flexibility in providing additional injection flow rate when needed during field development.

The main differences between systems being developed is the approach selected for the prefiltration system, the purpose of which is to remove enough solid components to reduce fouling of the nanofiltration membranes.

Subsea water treatment and injection is particularly useful for development of marginal fields or existing fields where topside space is heavily constrained. Using a subsea station close to the wells can unlock production while keeping CAPEX up to 15% lower than for a topside treatment of equivalent capacity.

Subsea Separation

Subsea separation refers to separating oil, gas, water, and sand on the seabed, mainly on the basis of density differences between components. It is classified into two categories.

- Gas/liquid, or two-phase, separation, which involves oil and gas

- Liquid/liquid, or three-phase, separation, which removes water from the production stream

Regardless of the application, implementing a subsea separation system helps reduce backpressure on the subsea wellheads to increase oil recovery and extend productive field lifetime while optimizing the topside.

Subsea gas/liquid separation improves flow assurance while optimizing overall production operability and fluid processing on the topside. For gas-condensate fields, gas/liquid separation improves production fluid transport from wellheads to the host by reducing liquid accumulation in the flowlines, flow instabilities (slugging), and issues related to hydrates and wax deposits, all of which could potentially shut down production.

For brownfields, subsea liquid/liquid separation allows removing most of the produced water at the seabed, eliminating the need to transport high volumes of water from deep water and enabling cost-effective development of marginal fields by connecting them to existing infrastructures.

Utilities and Control System

One potential solution for CAPEX reduction in offshore projects consists of simplifying or even eliminating the umbilical transporting the utilities from the production unit to the wells. To do so, the authors say the use of hydraulic fluids should be minimized or eliminated through the development of a barrier fluidless pump and an all-electric control system. They recommend subsea chemical storage and injection systems to eliminate the tubes from the umbilical.

Conclusions

- Subsea pumping is the most-implemented subsea technology and is considered a mature solution. Suppliers are now working on higher-power pumps and barrier fluidless pumps. CAPEX savings are obtained, for instance, when considering a hybrid loop with a pump instead of a conventional loop for long tiebacks.

- Subsea distributed heating is a booming technology for long tiebacks. It offers not only CAPEX savings, but also simplifies operations by removing the need for live oil displacement during shutdowns. The next challenge is to adapt the technology to deeper waters.

- Subsea gas/liquid separation and gas compression, while somewhat confidential currently, should be implemented increasingly in coming years with the increased role of gas in the energy sector.

- Liquid/liquid separation is also confidential at the time of writing but could play a major role in future brownfields to maximize the use of existing flowlines and risers and to reduce the volume of fluid handled topside.

- Subsea seawater treatment and injection will assume greater importance with the increasing number of subsea tiebacks and topside space constraints.

- Another step to develop longer subsea tiebacks consists of using all-electric control systems, subsea chemical storage and injection systems, and barrier fluidless pumps to remove the umbilical. The next question will be how to minimize the costs of the power chain required to feed the subsea equipment. The authors believe that the challenge can be answered through local power generation, including wind power farms.