Multi-layered coloured paint designed to cool buildings by reflecting the sun could become an eco-friendly alternative to air conditioners

- Coloured two-layer paint can dramatically cool building surfaces facing the sun

- Top layer absorbs light and a porous underlayer reflects infrared to resist heating

- US scientists’ new creation could also help keep vehicles and data centres cool

A new form of doubled-layered coloured paint designed to cool buildings by reflecting the sun could become an eco-friendly alternative to air conditioners.

US materials scientists say their array of coloured multi-layered paints can dramatically cool sun-blasted surfaces by up to 28ºF (15.6ºC).

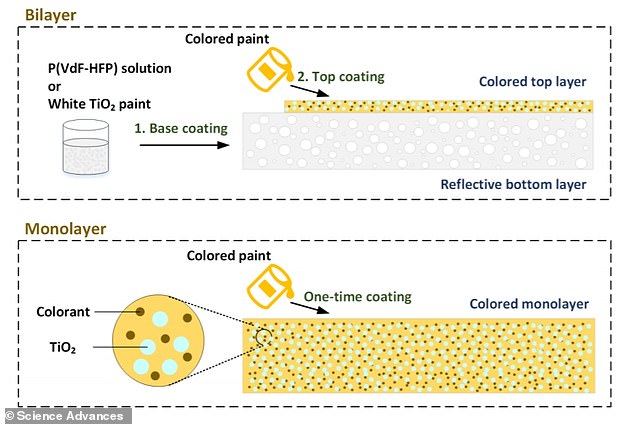

They consist of a top layer that absorbs light to achieve desired hues and a porous underlayer that reflects near-to-short infrared wavelengths to resist heating.

The porous paints, which come in black, blue, red and yellow, could cover buildings, vehicles and data centres and replace energy-intensive air conditioners.

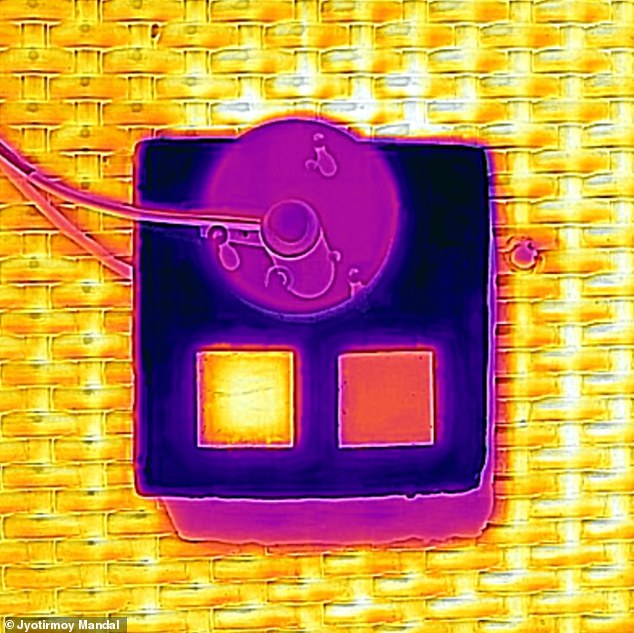

A single layer paint and the new bilayer paint on a thermal sensor. The bilayer coating (right) stays cooler under sunlight, compared to the single layer, as seen under infrared

Data centre servers – hardware that helps process masses of data for companies such as Facebook and Google – need to be kept in cool environments to offset the heat they generate.

This new range of paints could offer an environmentally-friendly way of reducing the power required to keep them constantly running.

‘The paintable bilayer designs, which substantially outperform commercial monolayer paints, demonstrate a practical and efficient solution to cooling coloured objects in a green and energy-saving manner,’ said study leader Dr Yijun Chen, at Columbia University in New York.

‘The performances show that the paint design can achieve both colour and efficient radiative cooling in a simple, inexpensive, and scalable manner.’

Scientists have previously sought surfaces that reflect sunlight to encourage cooling, but the designs are usually white which can produce a harmful, retina-searing glare.

Both the monolayer and bilayer coatings have near-identical colours to the human eye, as shown above

To overcome this, Dr Chen and colleagues developed a paint formed of 500-micrometer thick layer – or half a millimetre.

This ultra-thin layer contains interconnected micro-pores and nano-pores which reflect infrared light — a type of electromagnetic wave that transfers heat.

The top layer of the paint that absorbs light contains colourants and TiO2, or titanium dioxide, which is already used to add opacity to commercial paints.

They compared the different colours to traditional single-layer paints, finding that the new technology produced higher reflectance values for each colour.

‘The top layer absorbs appropriate visible wavelengths to show specific colours, while the underlayer maximises the reflection of near-to-short wavelength infrared light to reduce solar heating,’ Dr Chen said.

Top, the fabrication process of the bilayer coating. The relective bottom layer in the new paint powerfully reflects near-to-short infrared wavelengths. Bottom: the fabrication process of a monolayer coating. The monolayer contains colourants and TiO2 – titanium dioxide – which is already used to give opacity to products such as paints, plastics, paper, ink, food and medicines

‘Consequently, the bilayer attains higher reflectance compared with commercial paint monolayers of the same colour and stays cooler by as much as three to 15.6 degrees Celsius under strong sunlight.’

The scientists also managed to achieve different shades of the same colour by manipulating the top layer’s thickness.

A thin top layer of Sudan Blue produced a whitish blue and a thicker top layer appeared darker.

Photographs of of all four paint colours at different reflection angles – 25º on the left column, 45º middle and 65º right – with aluminium foil showing light reflection

The researchers also tested the technology to ensure it still performed in extreme heat.

They placed the paint outdoors, or in an oven, at 140 degrees Fahrenheit (60 degrees Celsius) for 30 days and found the paint still reflected light almost as well as at lower temperatures.

The paint, which is yet to be brought to market, has been detailed further in Science Advances.

Advertisement